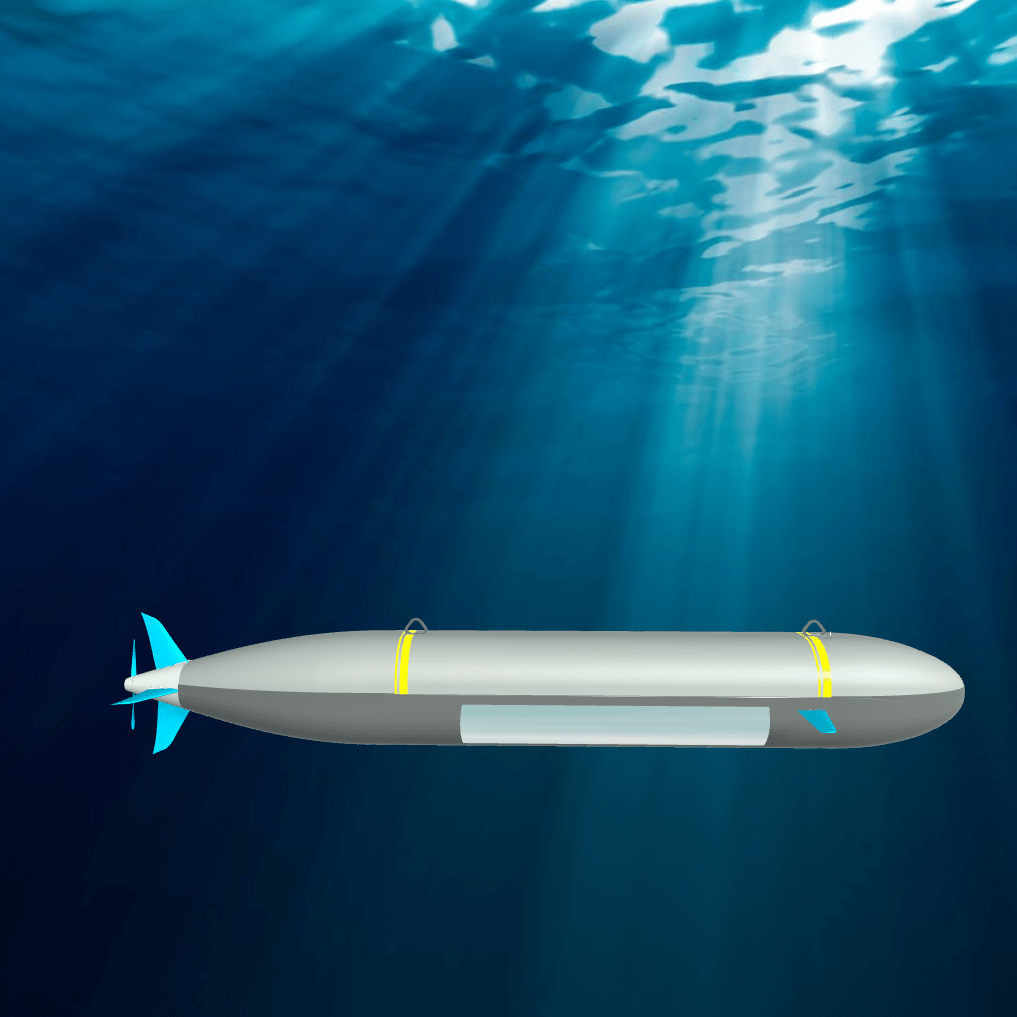

Defense - Undersea Systems

Ocean systems development and integration.

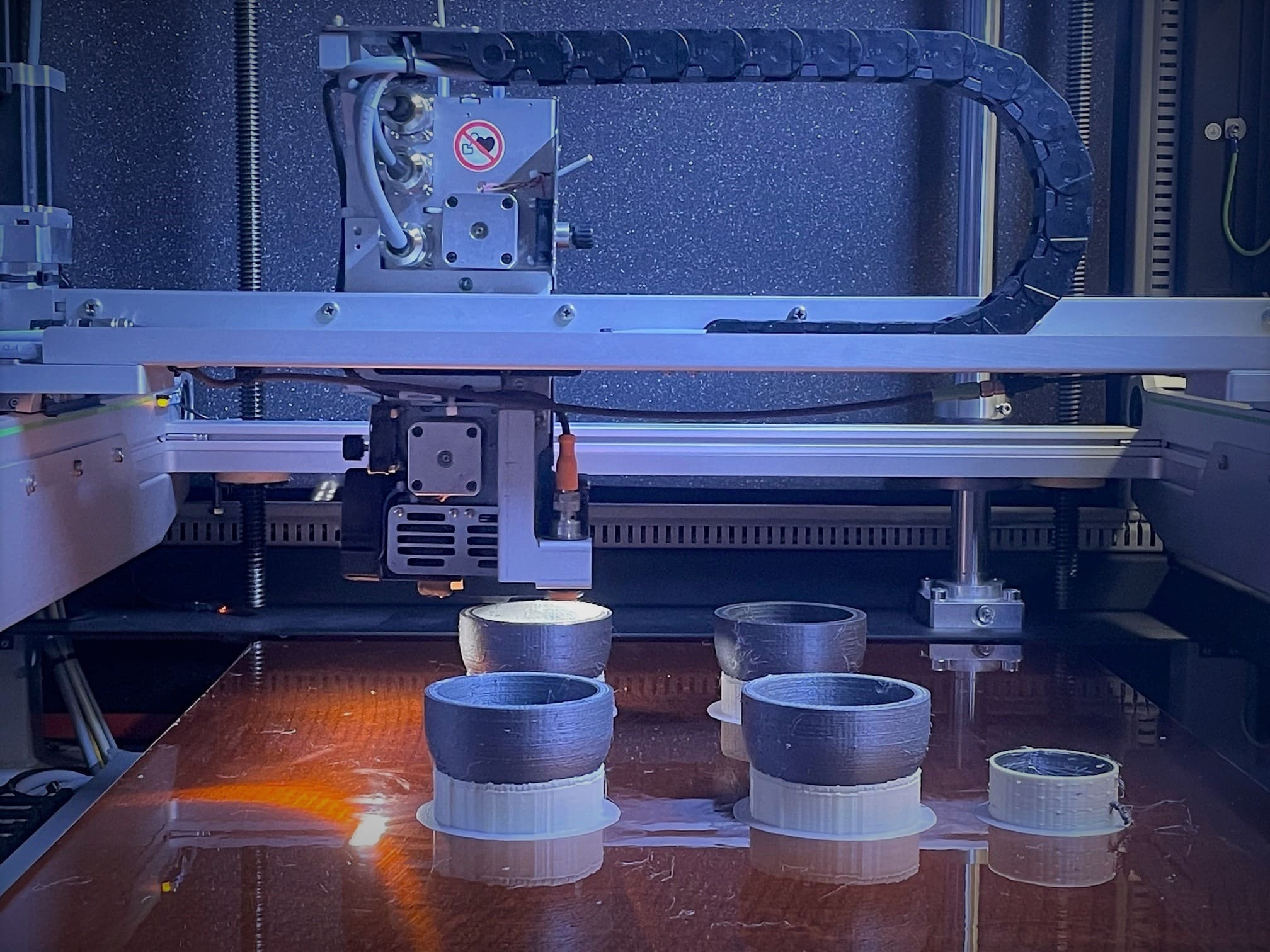

In an ever-expanding competitive battlespace, materials innovation is critical to maintaining strategic superiority in the undersea domain. CET is redefining unmanned vehicle mission duration and capability by developing and integrating UUV hull structures and systems out of carbon fiber, using both traditional and additive manufacturing methods and techniques.

Defense - Undersea Systems

From deep ocean to deep space, and everywhere in between

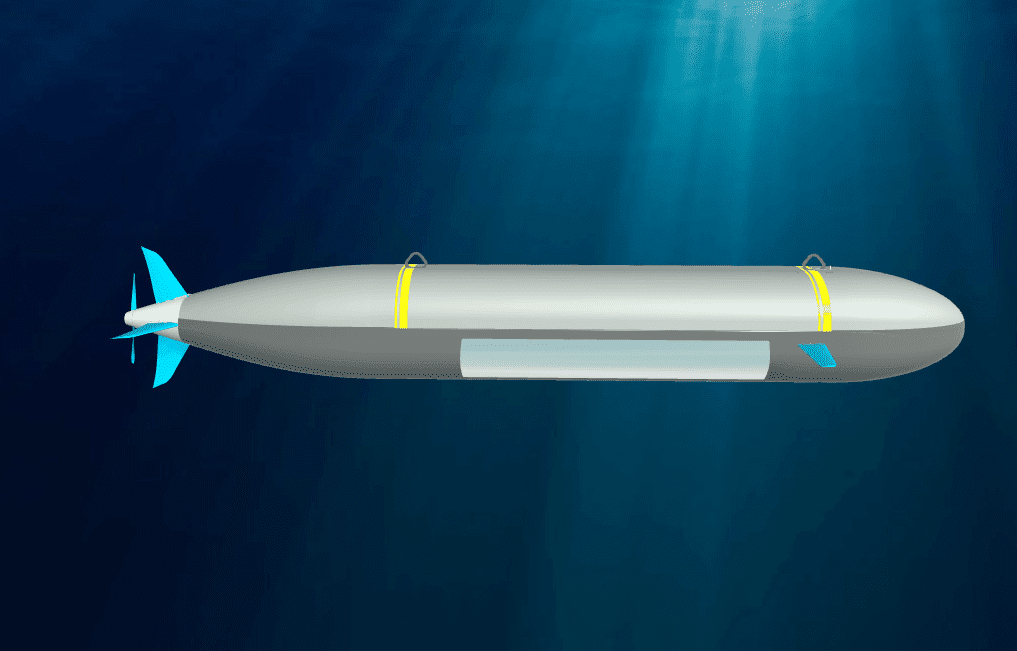

In the era of an ever-expanding competitive battlespace, the need for technological advancement is paramount as our nation hopes to out-compete our near-peer adversaries in the undersea domain, widely regarded as the battleground of the future. Traditionally, vehicles in this domain, Unmanned Underwater Vehicles (UUV’s), have been manufactured out of materials such as steel, aluminum, and titanium. These materials, although considered industry-standard, are sub-par alternatives to carbon fiber. CET has been working on the research, design, engineering, integration, and manufacturing of UUV hull structures, systems, and components since 2008. Our work has focused on all operational environments, including littoral, full ocean depth, and sub-polar ice cap.

The design efficiencies, weight savings, and non-reactive nature of carbon are among just a few of the reasons why our Navy sponsors have turned to CET to build prototypical vehicles to support their mission. Using advanced carbon composites inherently enhances mission duration while increasing internal volume, allowing for variability and maximization of payload capacity. Moreover, the experience CET has gained by its history of construction and modification of vehicles, as well as providing mission-specific data visualization and analysis tools for our customers, has provided us unique insight.

UUV Hull Structures and Systems Integration

Unmanned Underwater Vehicles (UUV’s) are robots that perform their mission under the surface of the water with little to no interaction with an operator. These systems have been manufactured in the United States since the 1950’s and serve a variety of user needs, including academic research, commercial exploration and monitoring, disaster investigation, and national defense, among others.

• Design, Engineering, Manufacturing

• Full-Ocean Depth

• Long-Endurance Missions

• Modular Hull Sections for Payload Variability

• Systems Optimization and Integration

Pressure Vessels and Sub-Sea Housings

Our design and engineering team understands the complex design and engineering requirements of unmanned systems, as well as the complicated operational environments that deployed UUVs must navigate and perform in. This experience has grown our capability to produce vehicle hull structures and systems that can reliably and repeatedly execute diverse mission sets under extreme loading conditions in austere and complex operational environments, including full-ocean depth.

• Design, Engineering, and Manufacturing

• Surface to Full-Ocean Depth

• Purpose-Built to Customer Specifications

• Long Length and Large Diameter

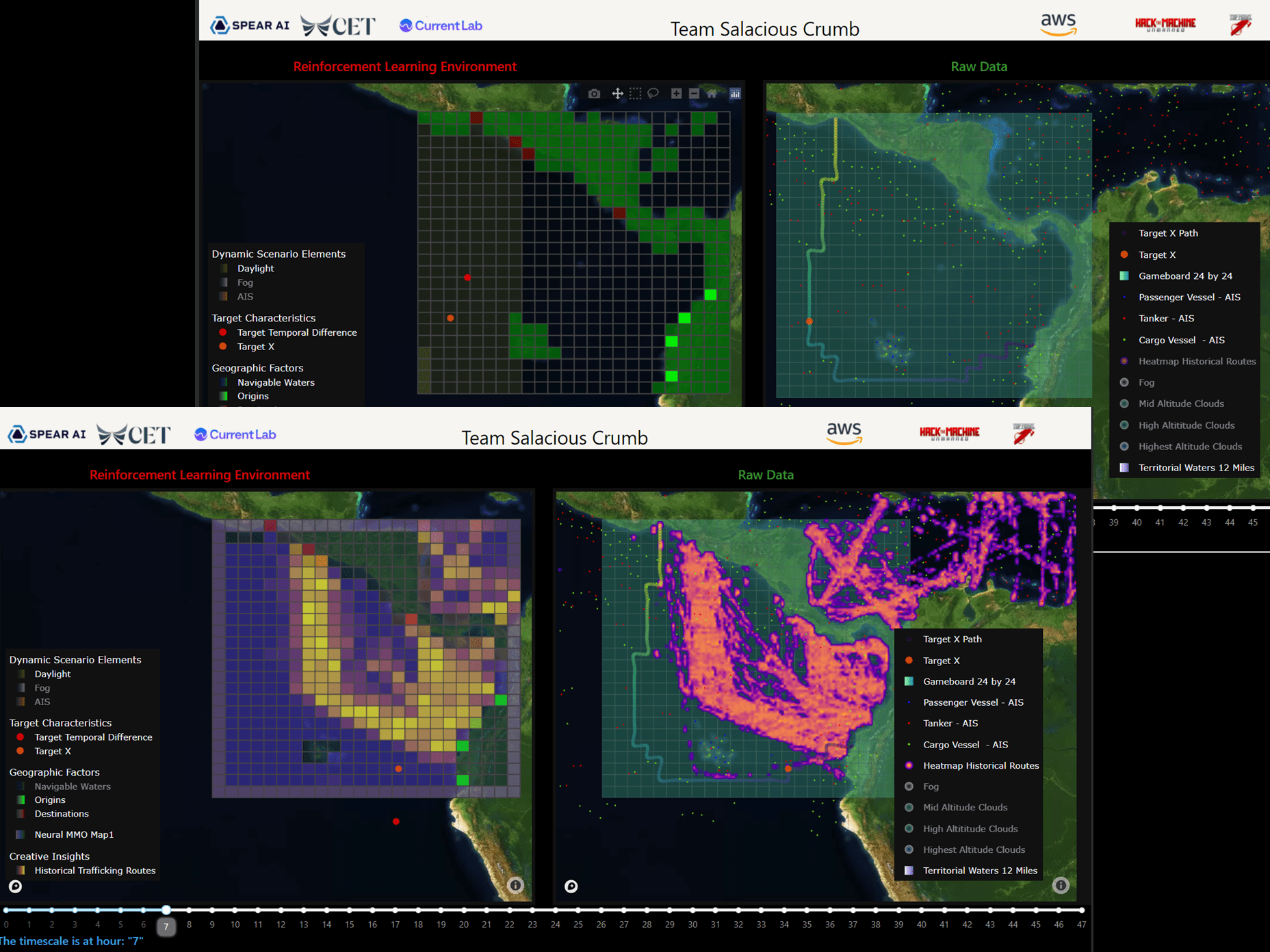

UUV Data Visualization and Analytics

CET’s experience extends beyond the domain of vehicles, with an additional research and development focus on carbon fiber pressure vessels. Our manufacturing capability includes vessels functional up to full-ocean depth, and in a variety of diameters and lengths.

• UUV Mission Planning and Performance Data

• Long Duration Mission Visualization (20+ days)

• Vehicle Positioning, Ballast, and Control Surface Optimization

• Risk Mitigation and Increased Mission Success

Carbon Fiber Pressure Vessels

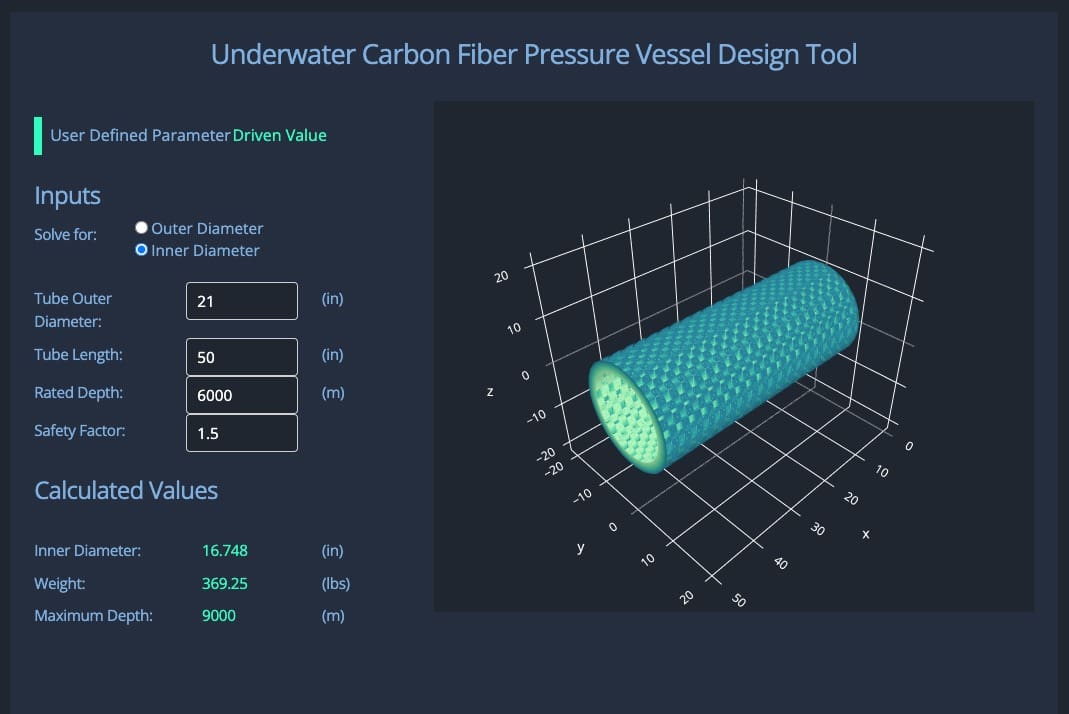

Through comprehensive engineering studies conducted in partnership with the College of Engineering at the University of Rhode Island, CET has developed engineering models to optimize the fabrication of underwater carbon fiber pressure vessels. These models have been thoroughly validated and proven through testing at the Woods Hole Oceanographic Institute (WHOI) Hydrostatic Test Facility.

Try The Tool